Paver Block Making Machine Morbi India

Let’s look at this machine’s operation theory. The production of blocks requires stone powder, slag mining slag, industrial stone and pulverized coal ash industrial cement, industrial sand, and various other substances in an equal proportion and a water mixture as the raw material. It is crucial to utilize the right proportion of material to avoid damage to the machine. The essential component is cement. Be sure to use it. Employed paver block making machin morbi india.

The machine making paver block making machine manufacturers morbi india uses vibration and pressure to create various types of concrete blocks through various molds. It is pressed using the highest pressure to make high-quality cement hollows and pavement blocks. The block-making machinery is also called block-making machines that aren’t burning since it doesn’t require burning for the entire process.

Since the dawn of time, construction has been an integral part of our lives and has played a significant role in helping get us to where we are today. Construction blocks constitute the primary element in any construction. Presently, we have two main kinds of blocks available to us: Bricks and paver block making machine price in india. They also own a concrete Block Making Machine and Brick Making Machine to manufacture these blocks. They make production speedy and efficient. Although both serve their functions effectively, Concrete Block Making Machines and Concrete Blocks are more effective than their competitors. Let’s find out why concrete blocks can be better than bricks.

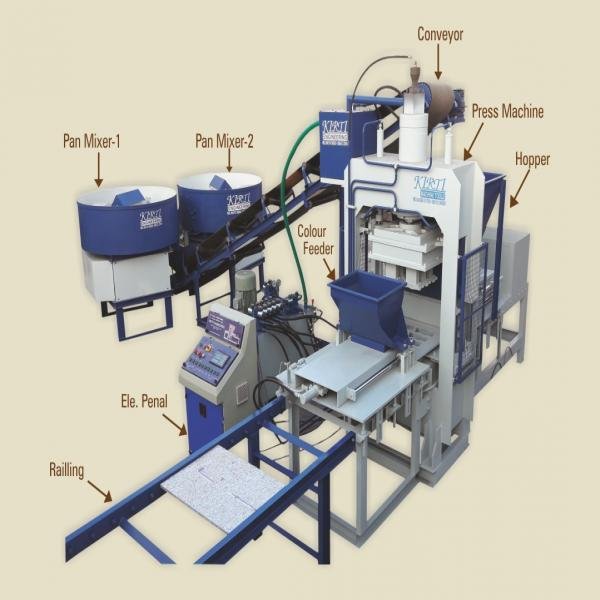

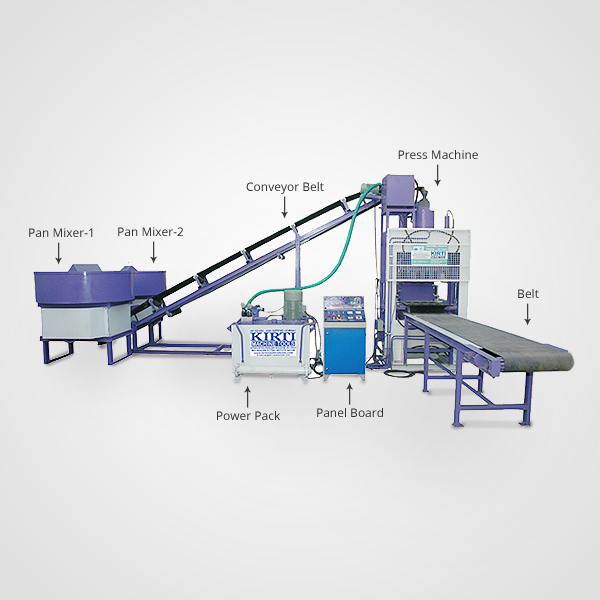

It uses hydraulic oil as the primary working media to ensure the machine’s work is done without waste. There are four essential elements: the machine’s primary hydraulic pumping station, a control panel, the pallet, and a blocked conveyor. Blocks of concrete composite paver hollow blocks, solid blocks, and slabs can all be produced with the help of the machine. It meets all needs for making high-quality interlocking paver block machine price morbi india.

interlocking paver block machine price in india are two of the primary kinds of automation available to block-making machines. Fully automated machines controlled by PLC are easy to operate. Semi-automated machines, however, are dependent on human interaction. It also has less output capacity than fully automated machines due to the use of the most recent technologies and features. Fully automatic machines are more costly in comparison to semi-automatic models.

The machine for making paver block making machine morbi india uses a method that can employ various innovative techniques, like hydraulic discharge and omnidirectional automated movement. To create a highly-performing machine, the makers of Mobile Block machines use high-quality steel and precise welding. Mobile block machine makers are also proficient in combining premium and various functional components to ensure consistent functioning.

Paver Block Making Machine Manufacturers Morbi India

The advanced control system utilized by the block machine is able to significantly increase the efficiency of work and decrease the intensity of labor. Since its introduction into on the marketplace, the automated block machine has become popular. If you have the funds to invest in an automated brick making plant is the ideal choice for customers since it allows you to finish your projects faster paver block making machine manufacturers morbi india.

paver block making machine price in india is a lightweight precast machine that is capable of handling huge quantities of production and reinforced panel manufacturing. Since there are less processing steps as compared to traditional tilt cake manufacturing, higher quality products are produced. Below are some advantages of the PLC System Full Automatic Block Machine:

The cost of raw materials is low. interlocking paver block machine price morbi india cinder natural sand, chemical or slag and other resources are utilized as raw materials for the block machine’s automatic. These components are not just easy to find and use, but they also aid in saving money.

We all know that the price of a block maker is determined by many variables, including the type, brand, materials and models, the manufacturer transportation method, and after-sales service and many more. If you are looking to buy an efficient machine, the cost of the machine is an important factor to take into consideration. But, price isn’t the only factor that affects the final decision. Be cautious of manufacturers of block equipment who offer rates substantially lower than the rates offered by their competitors. Automated block machines are affordable from reliable interlocking paver block machine price in india,

If you have a price in your mind, look for a variety of manufacturers and get quotations paver block making machine morbi india. Pick an established brand that meets you budget. Naturally, you must be able to stick to a budget. You can get a satisfying block machine that is automated available at a reasonable cost by doing this.

Paver Block Making Machine Price In India

For construction, the automatic brick-making machine can be used for various options. It can produce hollow blocks, interlocking bricks, solid bricks, and other types and sizes of bricks. They are utilized to build roads, gardens, and other buildings. Additionally, since the bricks produced by the independent brick plant are of high quality, it is possible to sell them.

Paver Block making machines are generally used to create blocks. the most common areas for use include driveways, pavements, patios, town center precincts, and road pavement. The significant advantage of paver bricks over similar materials is that they can be lifted later and removed and replaced. This permits remedial work to be done underneath the paver’s surface without leaving a permanent trace after replacing the paving bricks.

They are produced using vibration and compression to ensure the settlement of the material. This allows greater strength and improved outcomes. The process of making paver blocks is comprised of four fundamental methods, including mixing, molding, cubing, and curing. As a top Paver Block Machine Manufacturer, we are concerned with the security, strength, quality, design, and durability of our machine for paver bricks.

Understanding the paper size, you’ll need to create your outdoor areas requires expertise and knowledge. You may decide to utilize large-format paver blocks, but it is essential to know that more giant paver blocks diminish the impression of the patio’s dimensions. The larger paver blocks are more noticeable and draw attention. In addition, using smaller paver blocks gives an impression of a more extensive and considerable patio since smaller pavers are simpler and more widespread.

KIRTI MACHINE TOOLS

Satwara Estate, Panchasar Road, Morbi – 363641 ( Gujarat ) India

+91 9601008800, +918866320614

info@kirtimachinetools.com

Contact Us

Copyright © 2022 Kirti Machine Tools. All Rights Reserved.